Professional R&D, production, sales and after-sales integration.

We have many years of experience in R&D of automation technology and laser technology

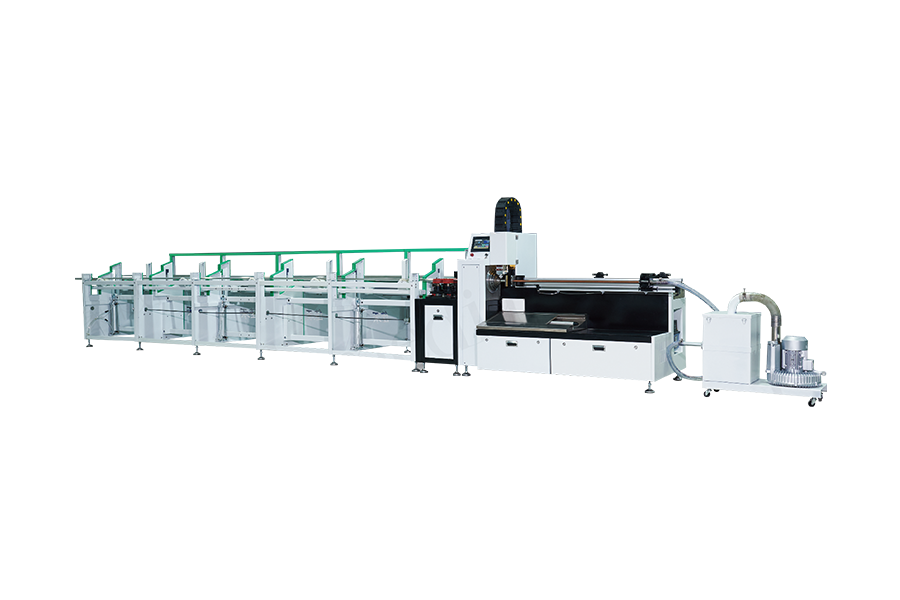

CNC Laser Pipe Cutting Machines represent a major advancement in industrial technology, moving far beyond traditional cutting methods through the integration of artificial intelligence. These systems deliver unprecedented levels of automation and precision in pipe processing, making them indispensable in today's manufacturing landscape. As global industries increasingly adopt IoT-enabled production and predictive maintenance strategies, these intelligent machines have become central components of modern smart factories. This article explores how AI-enhanced CNC Laser Pipe Cutting Machines are driving down operational costs while simultaneously improving product quality across sectors such as automotive manufacturing, industrial machinery, and construction equipment.

AI-Driven Optimization for Enhanced Precision

The incorporation of artificial intelligence has transformed how CNC Laser Pipe Cutting Machines operate. Advanced algorithms continuously analyze cutting processes in real-time, automatically adjusting parameters to maintain optimal performance. This intelligent adaptation allows the machines to compensate for material variations, temperature changes, and other factors that traditionally required manual intervention. The AI system can instantly modify laser intensity, focus, and cutting speed based on material thickness and composition, ensuring consistently perfect results regardless of input variations. This capability proves particularly valuable in industries where millimeter-level precision is critical, such as aerospace and medical equipment manufacturing.

Predictive Maintenance Through Smart Monitoring

Modern CNC Laser Pipe Cutting Machines come equipped with comprehensive sensor systems that monitor every aspect of machine operation. These sensors track component wear, laser calibration accuracy, energy consumption patterns, and overall system health. The collected data enables predictive maintenance by identifying potential issues long before they cause downtime. Maintenance alerts are generated automatically, allowing technicians to schedule repairs during planned maintenance windows rather than dealing with unexpected breakdowns. This proactive approach significantly increases production uptime while reducing emergency repair costs and extending the machine's operational lifespan.

Seamless Integration with Digital Manufacturing

The compatibility of modern CNC Laser Pipe Cutting Machines with digital twin technology represents another leap forward in manufacturing efficiency. Factories can now create virtual replicas of their cutting processes, testing different parameters and scenarios without consuming physical materials. This digital simulation capability allows manufacturers to optimize cutting strategies, identify potential problems, and train operators in a risk-free environment. The transition from virtual testing to physical production becomes seamless, with optimized parameters transferring directly to the actual machines. This integration significantly reduces material waste during setup and process optimization phases.

Sustainable Manufacturing Through Intelligent Resource Management

Environmental considerations have become increasingly important in manufacturing, and AI-equipped CNC Laser Pipe Cutting Machines contribute significantly to sustainability efforts. The AI systems calculate the most material-efficient cutting patterns, maximizing usage and minimizing waste. Advanced nesting algorithms ensure optimal material utilization, typically reducing waste by 20-30% compared to conventional methods. Additionally, the machines' energy management systems optimize power consumption based on workload requirements, further reducing their environmental impact. These sustainability features align perfectly with corporate ESG initiatives while also delivering substantial cost savings.

Adaptability Across Diverse Applications

The versatility of AI-enhanced CNC Laser Pipe Cutting Machines allows them to handle an enormous range of materials and applications. From stainless steel and aluminum to copper and specialized alloys, these machines maintain consistent performance across different material types. The automatic adjustment capabilities make them equally effective with thin-walled tubing and thick-walled pipes, requiring minimal operator intervention between job changes. This flexibility makes the technology suitable for everything from high-volume automotive production to custom architectural projects, providing manufacturers with a single solution for diverse cutting requirements.

User-Friendly Operation and Workforce Development

Despite their advanced capabilities, modern CNC Laser Pipe Cutting Machines are designed with operator convenience in mind. Intuitive touchscreen interfaces, guided setup procedures, and automated calibration features make them accessible to operators with varying skill levels. The AI systems provide real-time guidance and error prevention, reducing training time and minimizing operational mistakes. As manufacturing evolves toward increasingly automated environments, these machines help bridge the gap between traditional operator skills and future technological requirements, supporting workforce development while maintaining productivity.

The Path Toward Fully Autonomous Manufacturing

The ongoing development of AI technology points toward even greater autonomy in pipe cutting operations. Future iterations will feature enhanced self-diagnosis capabilities, automated quality control systems, and deeper integration with factory-wide automation networks. The machines will increasingly communicate directly with material handling systems, inventory management software, and other factory equipment, creating truly interconnected manufacturing environments. This evolution will further optimize production workflows while allowing human operators to focus on higher-level tasks such as process optimization and quality assurance.

English

English 中文简体

中文简体 русский

русский