Professional R&D, production, sales and after-sales integration.

We have many years of experience in R&D of automation technology and laser technology

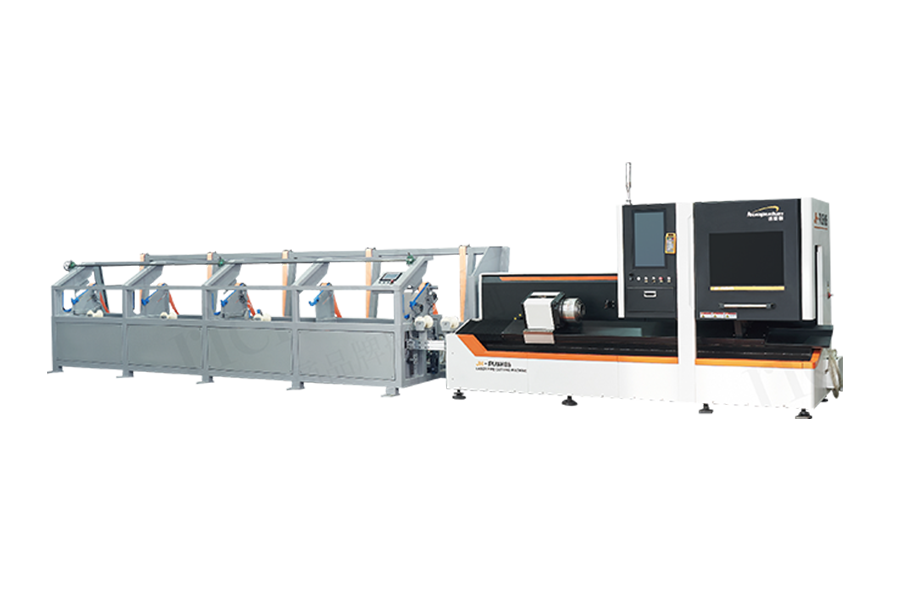

In modern manufacturing, precision and efficiency are critical to meeting production demands. The CNC Pipe Laser Cutting Machine has emerged as a valuable tool for industries that require consistent and accurate pipe cutting. Unlike traditional methods, this machine integrates computer numerical control with laser technology, offering a reliable solution for fabricators seeking precise outcomes. Its influence can be observed across various sectors, including construction, automotive, and metal fabrication.

Enhancing Accuracy in Industrial Settings

Accuracy is a fundamental aspect of industrial production. The CNC Pipe Laser Cutting Machine allows operators to achieve precise cuts on pipes of different materials and thicknesses. By relying on computer-guided paths, the machine less errors that often occur with manual cutting methods. This precision ensures that each piece meets design specifications, which is particularly important for projects where tight tolerances are necessary. Compared to older methods, the machine reduces inconsistencies and enhances overall product quality.

The role of the Automatic Pipe Cutting Machine in this context is also significant. By automating certain repetitive tasks, the machine helps maintain consistent cutting quality across large production runs. Its integration into workshops reduces the likelihood of human error and allows for smoother operations. While the CNC laser cutting machine focuses on precision, the Automatic Pipe Cutting Machine complements it by managing volume efficiently, ensuring that both accuracy and productivity are maintained.

Improving Workflow Efficiency

One of the main advantages of the CNC Pipe Laser Cutting Machine is its ability to streamline production workflows. Operators can program complex cutting patterns that would be difficult to achieve manually. This reduces the need for secondary operations and saves time on each project. Furthermore, combining the CNC laser cutting machine with an Automatic Pipe Cutting Machine allows factories to handle larger workloads without sacrificing quality. The two technologies work together to balance speed and precision in industrial environments.

Maintenance and adaptability are also important considerations. The CNC Pipe Laser Cutting Machine is designed to accommodate various pipe diameters and materials, providing flexibility for different applications. Regular maintenance ensures that the machine continues to operate accurately, reducing downtime and prolonging service life. Similarly, the Automatic Pipe Cutting Machine supports workflow continuity by enabling operators to focus on programming and monitoring rather than performing repetitive manual cuts.

Applications Across Industries

The use of the CNC Pipe Laser Cutting Machine spans multiple industries. In construction, precise pipe cuts contribute to reliable plumbing and structural systems. In automotive manufacturing, the machine enables the production of components that fit exact specifications, improving assembly quality. Even in metal fabrication workshops, these machines facilitate creative and functional designs by delivering accurate cuts that adhere to engineering requirements. Paired with an Automatic Pipe Cutting Machine, production lines can maintain consistent quality across all projects.

The integration of the CNC Pipe Laser Cutting Machine in industrial settings has significantly influenced manufacturing precision. Its computer-controlled laser cutting ensures consistent and accurate results, while the Automatic Pipe Cutting Machine supports efficiency and volume management. Together, they contribute to improved workflow, reduced errors, and enhanced production capabilities. As industries continue to adopt advanced technologies, the combination of these machines illustrates a shift toward more precise, reliable, and productive manufacturing practices.

English

English 中文简体

中文简体 русский

русский