Professional R&D, production, sales and after-sales integration.

We have many years of experience in R&D of automation technology and laser technology

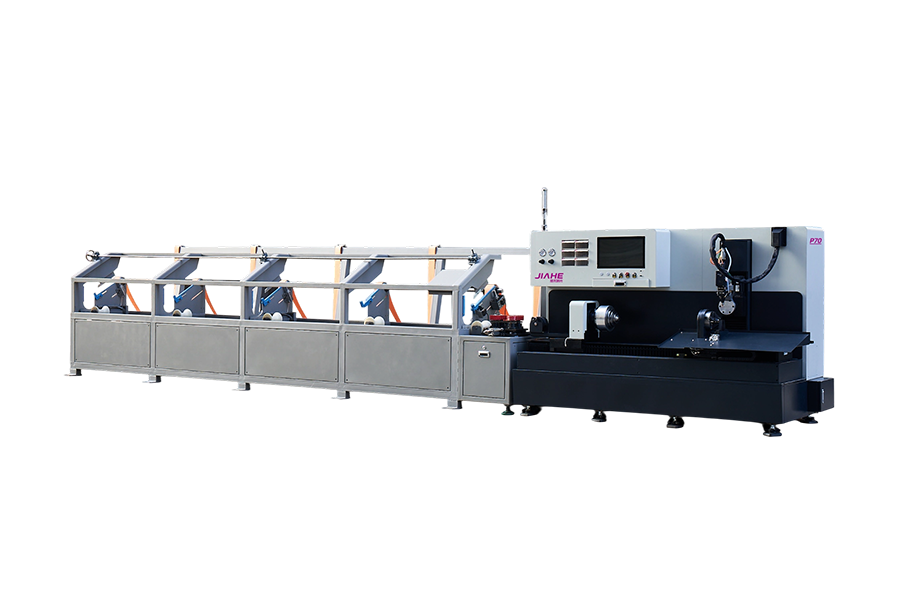

In recent years, global manufacturers have been actively discussing how to balance productivity, flexibility, and cost control under growing market pressure. From metal fabrication forums to LinkedIn and YouTube factory tours, efficiency-driven automation has become a clear focus. In this context, CNC Laser Pipe Cutting has emerged as a core topic among engineers and procurement teams, while the Automatic Pipe Cutting Machine is increasingly seen as a practical solution for scaling production without sacrificing consistency. As a professional manufacturer, we see these technologies not just as equipment, but as long-term tools that reshape how modern workshops operate.

Why Automation Is Gaining Attention Across Global Markets

Overseas buyers are no longer only asking about machine speed or basic specifications. Instead, discussions often revolve around reliability, repeatability, and ease of integration. Many fabricators face challenges such as labor shortages, rising training costs, and complex order requirements. Automated pipe cutting systems respond directly to these concerns by reducing dependence on manual processes and ensuring stable output over time.

From a manufacturing perspective, automation also allows workshops to standardize workflows. Once cutting programs are set, machines can operate with minimal adjustment, helping teams maintain consistent quality even when production volumes fluctuate.

Precision as a Foundation for Quality Manufacturing

Precision is one of the most frequently mentioned benefits in social media discussions around laser cutting technology. CNC-controlled laser systems allow pipes to be cut according to digital designs, reducing deviations caused by manual measurement. This level of accuracy supports tighter assembly tolerances and smoother downstream processes such as welding or bending.

For manufacturers, precision is not just about clean cuts—it directly affects material utilization and overall efficiency. When cutting results are predictable, planning becomes easier and rework is minimized. This reliability is especially valuable for customers handling custom projects or multi-batch orders.

How Automatic Pipe Cutting Improves Daily Operations

An automatic pipe cutting setup simplifies routine production tasks and reduces operator fatigue. Compared with traditional methods, automated machines support continuous operation and stable performance, even during long production cycles. From our experience as a manufacturer, this consistency helps customers improve workflow stability and manage deadlines more effectively.

Key operational advantages often highlighted by users include:

- Reduced manual handling during cutting stages

- Easier transition between different pipe sizes and profiles

- More predictable production scheduling

These factors contribute to a smoother factory environment, where operators can focus more on quality control rather than repetitive manual work.

Safety and Workforce Considerations

Safety has become an important talking point across global manufacturing communities. Automated cutting systems help limit direct contact with cutting zones, reducing exposure to sparks, sharp edges, and heavy materials. While no machine replaces proper training, automation can lower the physical strain on workers and support safer operating habits.

From a long-term perspective, safer and more ergonomic equipment can also help manufacturers retain skilled workers. This human factor is increasingly important as experienced operators become harder to recruit in many regions.

Designed for Flexibility and Future Needs

Modern fabrication demands equipment that can adapt to changing requirements. CNC laser systems and automatic machines are designed to handle different materials, wall thicknesses, and cutting patterns without extensive reconfiguration. This flexibility allows manufacturers to respond quickly to new orders or market shifts.

As a producer, we emphasize designs that support easy software updates and modular upgrades. This approach helps customers extend the service life of their machines while staying aligned with evolving production needs, rather than replacing equipment frequently.

Manufacturer Insight: What Buyers Should Really Look For

Beyond surface-level features, buyers increasingly value long-term support, process stability, and practical usability. From our manufacturing standpoint, a well-designed machine should balance precision, durability, and user-friendly operation. Equipment that integrates smoothly into existing production lines often delivers greater value than machines focused on a single performance metric.

Clear communication, standardized manufacturing processes, and consistent quality control are also essential factors that buyers consider when selecting suppliers.

Moving Toward Smarter Production with Confidence

As automation continues to shape the global fabrication industry, investing in CNC Laser Pipe Cutting solutions and a reliable Automatic Pipe Cutting Machine is becoming a strategic choice rather than a trend. These technologies support accuracy, safety, and operational stability while helping manufacturers remain competitive in dynamic markets. For companies seeking efficient, adaptable, and future-ready cutting solutions, automated pipe cutting equipment represents a solid step toward smarter manufacturing and sustainable growth.

English

English 中文简体

中文简体 русский

русский