Professional R&D, production, sales and after-sales integration.

We have many years of experience in R&D of automation technology and laser technology

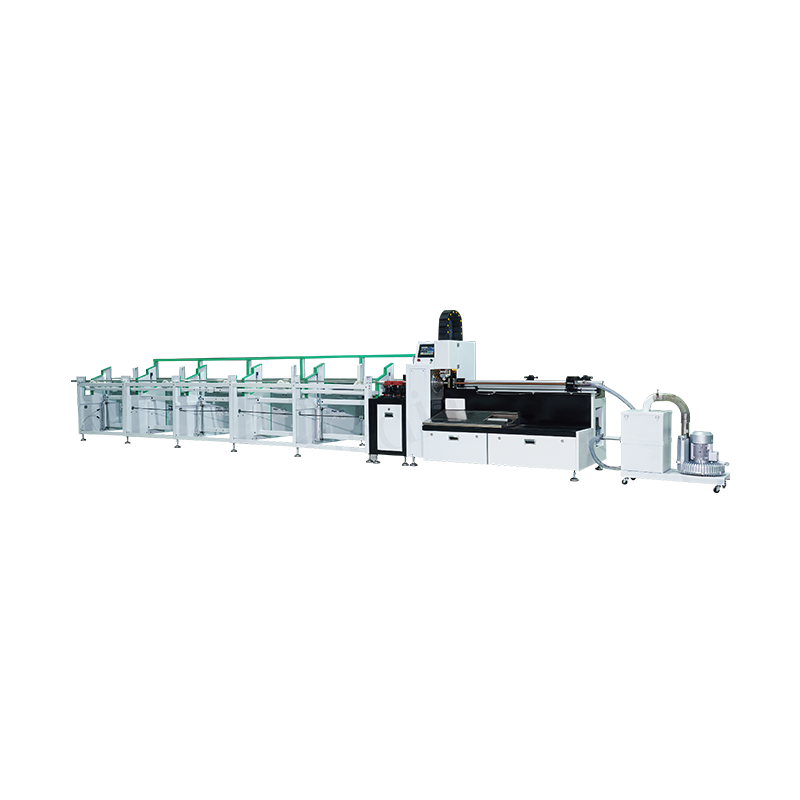

In today’s competitive manufacturing environment, efficiency, precision, and adaptability are key factors for success. Among the most impactful innovations in metal fabrication are CNC Laser Pipe Cutting systems and Tube Cutting Machines. These advanced technologies allow manufacturers to achieve highly accurate cuts, reduce material waste, and accelerate production timelines. As industries worldwide seek to optimize processes and meet growing demand for quality products, CNC Laser Pipe Cutting and Tube Cutting Machine have become central tools for fabricators, enabling consistent results and flexible operation across various metalworking applications.

Precision Cutting for Complex Designs

One of the most notable advantages of CNC Laser Pipe Cutting is its ability to deliver precise cuts, even on complex geometries. Unlike traditional cutting methods, laser technology ensures minimal deviation, allowing manufacturers to create intricate components for automotive, construction, and industrial applications.

Tube Cutting Machine units complement this precision by handling different tube diameters and materials with ease. Operators can switch between tasks without compromising accuracy, making these machines suitable for small-batch custom production as well as large-scale manufacturing projects. The combination of these technologies ensures high-quality results and reduces errors that can lead to costly rework.

Improving Production Efficiency

Time efficiency is crucial in modern fabrication. CNC Laser Pipe Cutting allows for faster processing compared to conventional mechanical cutting, significantly reducing production lead times. Automated controls enable continuous operation with minimal human intervention, freeing skilled workers to focus on other tasks.

Similarly, Tube Cutting Machine systems streamline workflows by enabling rapid cutting, sorting, and handling of materials. This efficiency not only reduces labor costs but also improves overall productivity, allowing companies to meet tight deadlines and maintain competitive advantage in international markets.

Versatility Across Materials and Applications

The versatility of these machines is another major advantage. CNC Laser Pipe Cutting can handle a wide range of materials, including stainless steel, aluminum, and carbon steel, providing consistent quality regardless of material thickness.

Tube Cutting Machine units are equally adaptable, capable of processing various shapes and sizes to meet diverse industrial needs. From creating structural components in construction to producing precision parts for automotive systems, these machines offer the flexibility required to address multiple manufacturing challenges.

Reducing Waste and Enhancing Sustainability

Modern manufacturers are increasingly focused on reducing waste and improving sustainability. CNC Laser Pipe Cutting uses high-precision technology that minimizes material scrap and optimizes the use of raw materials.

Tube Cutting Machine systems also contribute to sustainability by ensuring clean cuts and consistent material usage, lowering the environmental impact of production. By integrating these machines into fabrication processes, companies can achieve both economic and environmental benefits, aligning with global trends in responsible manufacturing.

English

English 中文简体

中文简体 русский

русский