Professional R&D, production, sales and after-sales integration.

We have many years of experience in R&D of automation technology and laser technology

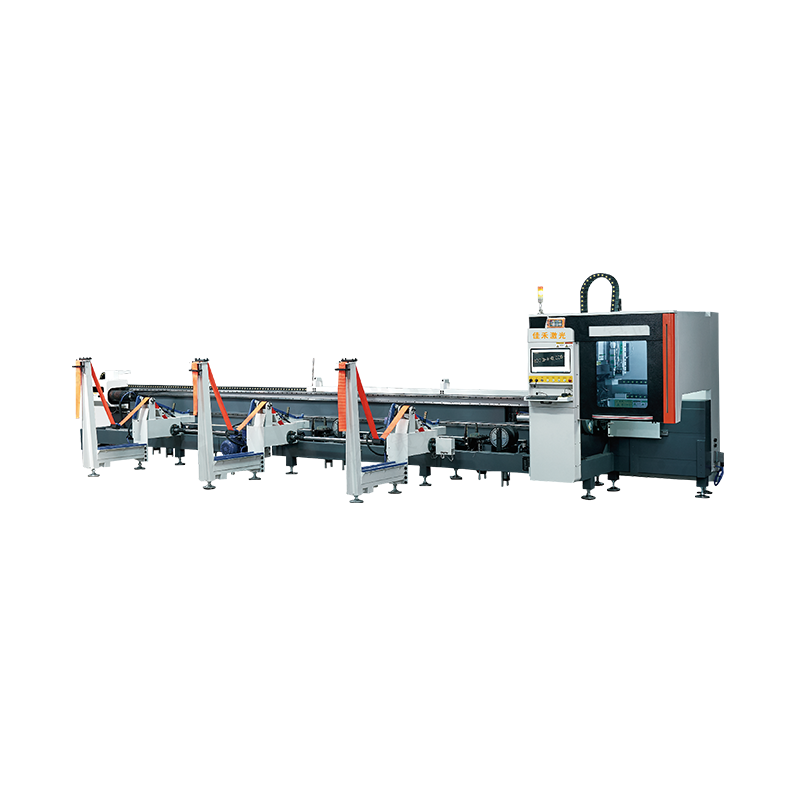

In the fast-paced world of metal fabrication, manufacturers are constantly seeking ways to increase productivity without sacrificing quality. CNC Laser Pipe Cutting and Tube Cutting Machine technologies have emerged as pivotal solutions for achieving this balance. By combining automation, precision, and versatility, these machines allow fabricators to complete tasks more efficiently, reduce errors, and maintain consistent output. The adoption of CNC Laser Pipe Cutting and Tube Cutting Machine has transformed production lines, enabling manufacturers to meet growing global demand while maintaining competitive advantage. Their growing popularity reflects the industry’s emphasis on faster, smarter, and more reliable manufacturing processes.

Automation for Streamlined Operations

A major advantage of CNC Laser Pipe Cutting is its automated control system, which enables continuous, hands-off operation. Operators can program complex cutting paths, adjust settings, and monitor progress remotely, reducing the need for manual intervention.

Similarly, Tube Cutting Machine units are designed to automate repetitive tasks, including tube positioning, cutting, and sorting. This level of automation not only improves production speed but also reduces the likelihood of human error, ensuring higher consistency and reliability in finished products. Modern facilities increasingly rely on these machines to support 24/7 operations, reducing downtime and maximizing throughput.

Precision and Accuracy

Precision is a defining feature of CNC Laser Pipe Cutting. Its laser technology delivers highly accurate cuts, even on intricate shapes and designs. This accuracy ensures that parts meet strict engineering tolerances and reduces material waste.

Tube Cutting Machine complements this precision by providing smooth, consistent cuts across different tube diameters and materials. Together, these machines enable manufacturers to produce complex components without compromising quality, which is especially important for industries like automotive, aerospace, and construction. Enhanced precision also minimizes the need for secondary processing, saving both time and cost.

Flexibility for Diverse Applications

Versatility is another reason these machines are transforming manufacturing. CNC Laser Pipe Cutting can process a wide range of materials, including stainless steel, aluminum, and carbon steel, accommodating various thicknesses and production requirements.

Tube Cutting Machine units offer similar flexibility, capable of handling different tube shapes and sizes. This adaptability allows manufacturers to switch between projects with minimal downtime, supporting both custom orders and large-scale production runs efficiently. It also allows businesses to explore new markets by accommodating specialized client requirements.

Cost Efficiency and Waste Reduction

Modern manufacturers increasingly focus on minimizing costs and material waste. CNC Laser Pipe Cutting enables precise cuts that maximize material usage, reducing scrap and lowering production costs.

Tube Cutting Machine further enhances efficiency by delivering clean, accurate cuts that eliminate the need for additional finishing work. Integrating these machines into production lines results in significant operational savings while contributing to environmentally responsible manufacturing practices. By reducing energy consumption and optimizing material use, these machines support sustainable manufacturing strategies.

Why CNC Laser Pipe Cutting and Tube Cutting Machine Are Crucial for Modern Fabrication

In today’s competitive market, efficiency, precision, and flexibility are critical for manufacturing success. CNC Laser Pipe Cutting and Tube Cutting Machine provide all three, helping manufacturers achieve high productivity, reduced errors, and consistent quality. For businesses seeking to modernize production, meet international standards, and stay ahead of competitors, CNC Laser Pipe Cutting and Tube Cutting Machine are indispensable tools that define the future of metal fabrication. By combining speed, reliability, and adaptability, these machines allow manufacturers to innovate, reduce waste, and meet evolving global demands.

English

English 中文简体

中文简体 русский

русский