Professional R&D, production, sales and after-sales integration.

We have many years of experience in R&D of automation technology and laser technology

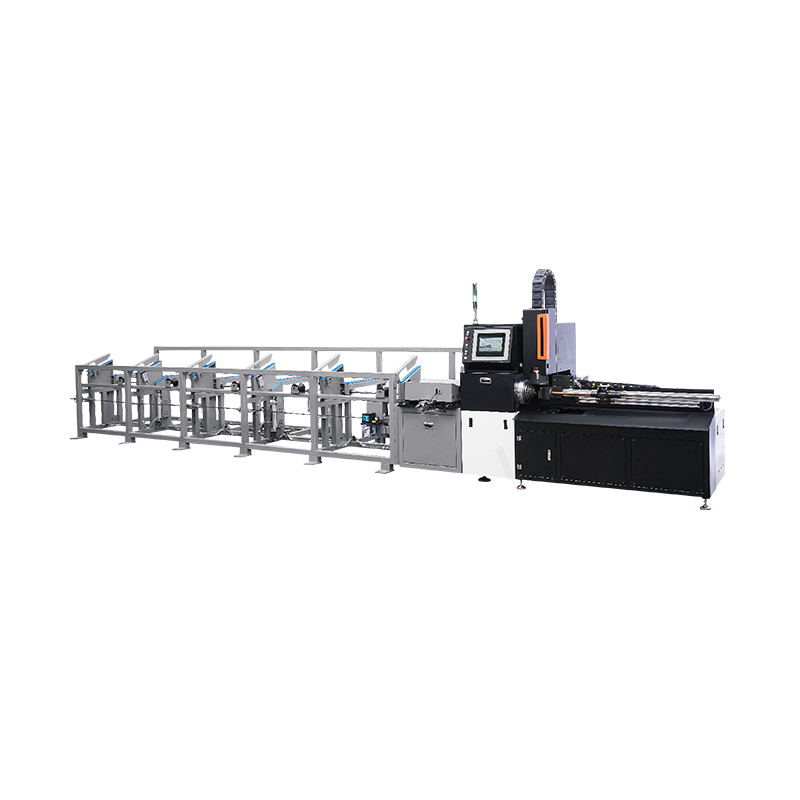

Across global industrial communities, one noticeable trend is dominating conversations: the rise of smart, automated cutting systems that streamline complex fabrication tasks. As companies look for efficient and more adaptable production tools, the Tube Cutting Machine has become a regular topic of discussion on overseas engineering forums. Meanwhile, technologically advanced CNC Laser Pipe Cutting systems are gaining attention for supporting cleaner cuts, digital control, and flexible applications across multiple industries.

Automation Is Becoming a Necessity—Not a Luxury

Manufacturers are operating in a rapidly evolving environment where product designs change frequently, and clients demand shorter delivery cycles. Traditional cutting methods often struggle with inconsistent performance or time-consuming adjustments. As a result, factories are turning toward automated solutions that minimize operator dependency and deliver predictable, steady cutting paths.

Automation allows companies to standardize quality while reducing production bottlenecks. This shift is widely discussed on international business networks, where workshop managers highlight how automated technology helps them keep pace with modern project requirements.

Why Are Businesses Prioritizing Clean, Stable Cuts?

Edge quality remains one of the most influential evaluation factors for cutting equipment. Poorly cut pipes create downstream problems—from welding complications to surface finishing delays—disrupting entire production lines. Manufacturers increasingly recognize that the stability of the cutting process directly influences overall production cost and efficiency.

For this reason, companies are searching for cutting tools capable of delivering cleaner, more uniform pipe edges. Overseas buyers often emphasize that high-quality cutting performance is crucial for maintaining consistency in industries such as automotive frameworks, machinery components, architectural structures, and furniture manufacturing.

Multi-Material Compatibility Becomes a Key Buying Criterion

Another global manufacturing trend is the shift toward diverse material usage. Companies no longer work with a single type of metal; they frequently handle lightweight tubes, corrosion-resistant alloys, structural steel, and other specialized materials.

Buyers want cutting systems that adapt to these variations without requiring extensive manual recalibration. Flexibility has become a major selling point. Machines that easily handle different thicknesses, diameters, and pipe geometries are gaining preference because they allow workshops to broaden their services and operate more competitively.

Smart Digital Features Attract Forward-Looking Manufacturers

Digitalization is transforming factory floors worldwide. Companies increasingly prefer machines that integrate seamlessly with design software and production planning platforms.

CNC-based cutting systems stand out because they offer digital input, automated cutting path generation, and easy access to stored profiles. This simplifies training, reduces operator errors, and aligns with the broader movement toward smart manufacturing.

Manufacturers aiming for future scalability consider digital connectivity essential. It ensures clearer documentation, faster setup, and better coordination between engineering and production teams.

Safety Enhancements Are Influencing Purchasing Choices

The global focus on workplace safety continues to shape buying decisions. Companies want equipment that minimizes direct human contact with cutting areas and provides reliable protective features. Automated pipe-cutting systems offer stable clamping, guided cutting paths, and enhanced shielding—key elements that help reduce risks.

Many industrial users value machines with straightforward operation panels and emergency-stop functions. These features reassure operators while helping companies comply with evolving international safety standards.

Why Workshops Seek Greater Operational Efficiency

Efficiency plays a significant role in maintaining smooth workflow across multiple project batches. Workshops managing tight deadlines, frequent design changes, and varying project sizes need cutting systems capable of fast, uninterrupted performance.

Equipment that maintains stable operation—even during increased workload periods—enables businesses to schedule tasks more confidently. This reliability allows workshops to support more clients and take on complex cutting jobs without adding stress to their daily operations.

The Industry’s Collective Shift Toward Long-Term Reliability

A noticeable trend across online manufacturing communities is the preference for equipment that provides reliable performance over long periods. Companies prioritize durability, ease of maintenance, and consistent output when selecting new cutting machines.

Workshops investing in advanced cutting technology experience smoother workflows, higher customer satisfaction, and long-term competitiveness. The shift toward durable, automated systems reflects the industry’s growing desire for dependable tools that evolve with market demands.

As manufacturing continues moving toward digital integration and more adaptive production processes, it is clear why global buyers are investing in advanced solutions such as the Tube Cutting Machine and CNC Laser Pipe Cutting. These technologies support greater precision, improved workflow safety, and enhanced production flexibility, making them valuable assets for forward-thinking fabrication businesses.

Manufacturers are making more thoughtful decisions about equipment purchases. Instead of choosing basic cutting tools that require frequent maintenance or rework, buyers increasingly prefer machinery that supports consistent quality and stable long-term operation.

Advanced cutting solutions help businesses operate with greater reliability, meet customer expectations, and build a stronger competitive advantage. Workshops that adopt automated systems often find it easier to take on complex projects and expand their capabilities.

As global manufacturing grows more dynamic, technologies like the Tube Cutting Machine and CNC Laser Pipe Cutting continue to attract attention from businesses seeking adaptable, precise, and efficient production tools that support the future of metal fabrication.

English

English 中文简体

中文简体 русский

русский